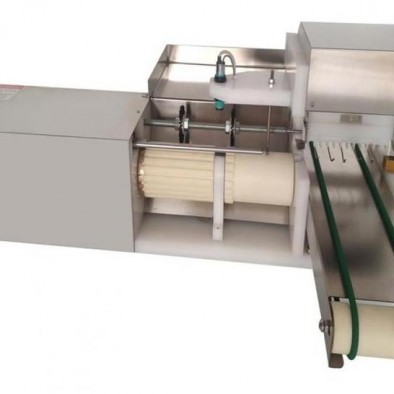

Lamb slicing machine

Fully automatic operation saves labor costs. The machine can cut out various types of thick rolls, thin rolls, long rolls, straight rolls, etc., with one machine for multiple purposes.

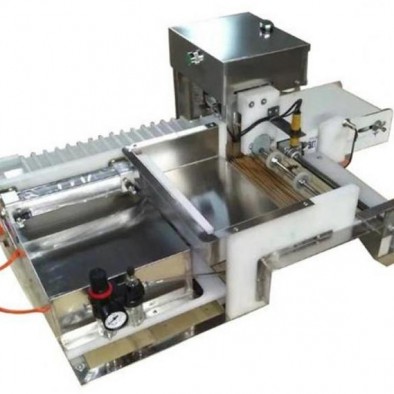

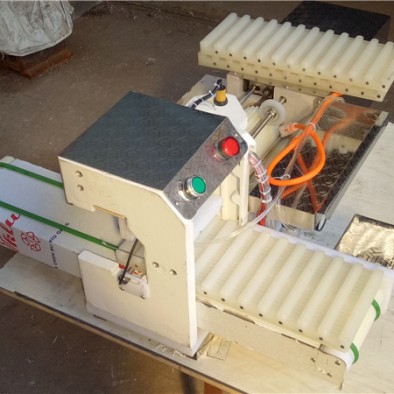

Food packaging machine

Operating various types of food packaging machine, bread packaging machine, cake packaging machine, vegetable packaging machine, fruit packaging machine and so on.

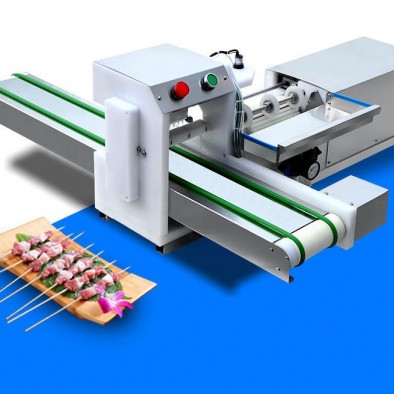

Meat skewers machine

Mainly used for various meat skewers, lamb, beef, The main types are:sheep Meat string machine,Cattle Meat string machine,Meat skewers machine etc., saving manpower and time.

We have 50 Years

Of Experiences

3000

Clients

2500

Projects

1000

Awards

latest Products

We are a professional manufacturer of lamb slicing machine, beef slicing machine, lamb skewering machine, beef skewering machine, meat skewer machine, food packaging machine, vacuum packaging machine. Please feel free to contact us by email: foodslicer@outlook.com